Projects

Recent Posts

Embedded systems requires programming skills and an important set-up effort. Control algorithm is typically implemented last with a PI feedback loop. However control theory provides many solutions to explore improving systems dynamic responses, perturbation rejection and robusness to model mismatch.

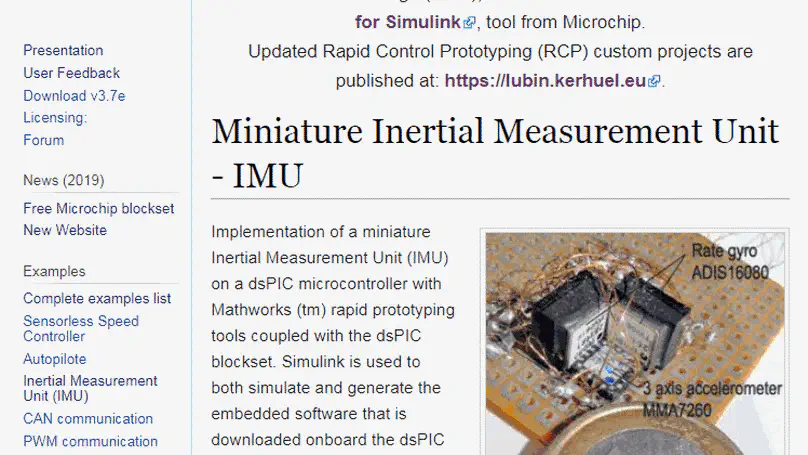

Interested in applied math, I developed a blockset for Matlab/Simulink targeting dsPIC microcontrollers in 2005. It enables focusing on the controller part using simulink simulation rather than on implementation problems. Rapid Control Prototyping (RCP) became possible on any dsPIC based board. It is embedded on cheap demo or custom board and does not required budget to aquire high-end tools like dSPACE, SpeedGoat, National Instrument alternative.

$$ \text{One push button} \left\{ \begin{array}{l} \text{- Generate C code} \\\ \text{- Compile} \\\ \text{- Upload & Run on the target} \end{array} \right. $$

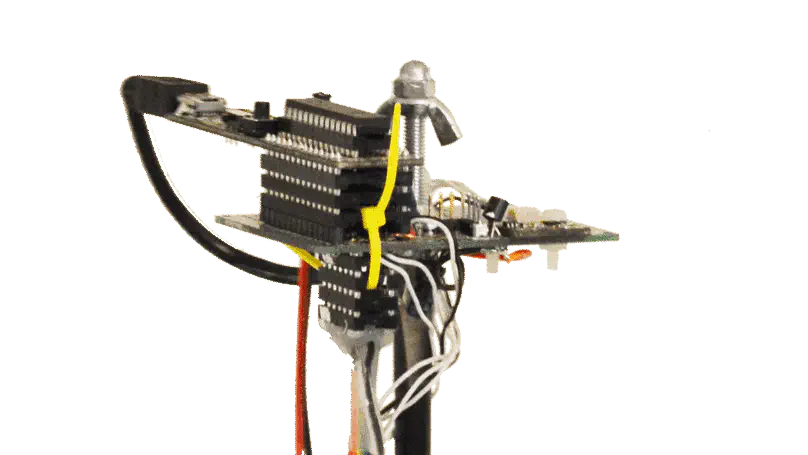

I used this dsPIC Target toolbox for my PhD thesis on bio-robotics from 2006 to 2009 on. It shorten path from the visual signal processing simulation and control of our aerial robot and replaced the original dSPACE platform in our lab.

The same approach was then used to develop data fusion algorithm on motion analysis in wearable sports article at MOVEA in 2010-2011.

I joined in 2011 Microchip Technology to pursue the development of the MPLAB blockset. The tool target dsPIC and was extended to target:

- dsPIC A

- PIC32 (MIPS core)

- SAMx2 (ARM Cortex M0+)

- SAMx5 (ARM Cortex M4)

- SAMx7 (ARM Cortex M7)

We implemented a rate-monotonic scheduler (multitasking system) and integrates completely to the MathWorks environment with support for PIL (Processor In the Loop), External-Mode…

The tool growth to target up to 650 chips. The development task and support was splitted in 2022. I will continue focusing on dsPIC new developments and support.

For company, scientists, and students, rapid prototyping enables focusing on ideas rather than getting lost into the details of embedded programming. Shortening the loopback $Simulation \Leftrightarrow Hardware $ allows to

- refine and validate a model thanks to early test

- develop controller using the system digital twin

- implement the final controller

- benefit from the wide MathWorks tools available

Electronics projects from this website use the Microchip blockset. Older project are available on my old website.

- Control Theory & applied math

- Embedded system

- Swimming

Ph.D Automatic, Signal Processing & Aerial Robotics, 2009

National Center for Scientific Research (CNRS) / University Montpellier II

Master of Research - Signal Processing and Digital Communication, 2004

University of Nice Sophia-Antipolis

Engineer - System on Chip, 2004

ESIEE Paris

Contact

- lubin@kerhuel.eu

-

19 rue Adrien Barthe

64100 Bayonne - Microchip Forum